As working from home transitions from a seemingly temporary precaution into the foreseeable status quo, the difficulties of having to perform all of my job functions remotely become more evident. Out of frustration, I set out to see if I could remedy some of my WFH woes by creating a tool... for tools.

As a member of our QC team, part of my job requires that I construct the testing fixtures I've designed; this almost always necessitates soldering, and often requires the use of rework and diagnostic tools. Fortunately, I have all of these tools available at home, but space constraints prohibit me from having a dedicated workspace where this equipment can remain set up.

Previously I had been setting up all of this equipment on my garage workbench, and disassembling it when finished. Set up and tear down time combined was about 20-30 minutes, but with some planning the impact of that time could be minimized by lumping all of the soldering and rework portions of my projects into one sitting. This seemed to work, but with a rise in cases where I needed to simply swap a resistor or close a jumper, a task that would normally take a few minutes now took upward of 30 if the equipment wasn't already set up - this needed fixing. So just as many schools, shops and labs already do, I decided to fix the problem by employing a cart to house the equipment I needed.

Design Details

The soldering/reworking/testing cart was designed with a four essential functions in mind:

- First, obviously, the cart must be able to hold and store all the tools I need to solder, rework, and diagnose electrical thingys with.

-

Second, and also obviously, the cart must be able to move the tools needed to the job.

-

Third, it needs to eliminate most of the set up and tear down time that would be needed if the tools were stored while not in use. This means having all the equipment set up and easily accessible.

-

Fourth, the cart itself must not cost more than $40 in raw materials. I already owned all of the tools prior to designing and building the cart, so the cost of the tools is not included in the $40.

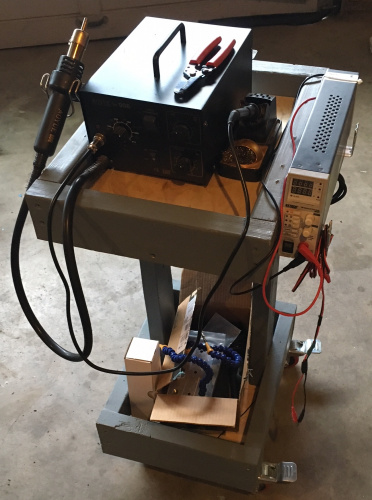

The design ended up being simple, but strong. The cart utilizes two platforms: an upper platform that supports the soldering and rework equipment, and a lower platform that holds supplies and hand-held tools.

The cart needed to be tall enough to be used with a table or desk, but low enough to be usable while, say, working in or under a car. The upper platform's base ended up being 32 inches above the ground. I opted to use 2x4s and ¼” plywood as the structural body and platform floor respectively (as an aside, 2x4’s are certainly overkill, and make the cart a little bulky, but they are also cheap, allowing more money to be spent on casters).

Both platforms are walled with the 2x4’s to prevent items from falling off or out, and three 2x4 sections act as struts between the two platforms. A caster is mounted at each of the four corners of the lower platform, giving it stability and the ability to be rolled and locked in place with ease. Painting the cart ended up being an easy way to clean the whole thing up, as well as making it easier to wipe down.

The main tools that reside on the cart:

- Hot-air rework and soldering station (combined)

- Switching DC power supply w/banana-to-gator clips and banana-to-barrel

- Digital multimeter

- Amp meter clamp

- Third arm

- Wire strippers

- Tweezers

- Side cutters

- Pliers

- Small ESD mat

NOTE: Mounting a small power strip to the cart meant that only one cord would need to be plugged in in order to power the non-battery powered items.

Has it made anything easier?

It certainly solved my set up and tear down issue. I can be set up and soldering within minutes, and in less than a minute the cart can be back in storage when finished. As a result, my workflow is far less disturbed, and in turn my productivity has risen. As for a non-vocational takeaway, I've procrastinated much less on personal soldering and electrical projects, and it's stimulating thinking of ways to improve the cart's setup.

In reality, there's nothing special about this cart. An equal or better example could be purchased online and delivered to your door in days, but there is something to be said for designing and building your own thing - I certainly found it more rewarding. On that note, next time you have a problem that needs solving, think about taking the time to create your own fix before you buy one - you might be surprised by what you can come up with.

No comments:

Post a Comment